Capacity ranges : 500 kg/hr to 18,000 kg/hr

Isaac boilers IB3S series three pass wet back boilers is an ideal choice for all commercial and industrial applications. IB3S series boilers provides fuel efficiencies that exceed four pass design.

Boilers are manufactured as per latest ASME Section VIII Div I standards in welded construction with 100% radiography of longitudinal and circumferential seams, thermal stress relieved after welding and hydro tested as per the standards. We also manufacture boilers as per, latest IBR Code.

The boiler is a three pass conventional wet back construction. The combustion chamber (furnace) form the first pass in which fuel is burnt and radiant heat is transmitted to the water contained in the shell.

Water level is maintained through level controller to make furnace, reversing chamber and smoke tubes in the boiler to be immersed in the water. Reversing chamber is located in the rear of the furnace, which ensures complete flue gases are turn around to entering the second pass.

Isaac boilers has the furnace located eccentrically with smoke tubes arranged in a staggered manner on both side of the furnace

Front and rear tube plates and the furnace are accessible for inspection and maintenance.

Shell and furnace diameter are larger to achieve low emission and required output is achieved quickly.

The front smoke box ensures complete turn around of the gases entering the third pass of the smoke tubes.

Generous heating surface is maintained in the boiler which ensures guaranteed performance.

Optimum gas velocities are maintained to ensure minimum pressure drop on gas side. Sufficient steam space and water holding capacity are provided to take care of steam load fluctuation.

Compact quick steaming, sturdy and reliable. Easy and simple to install

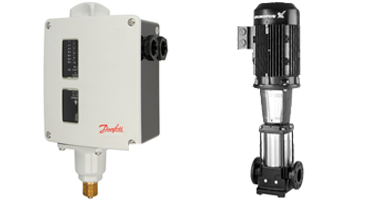

Boiler water level is controlled through using either float type low water cutoff system or through probe type level control system, which shuts the pump when the required level is achieved and allows the burner to start once level is reached.

Additional auxillary level controller is used for high level cutoff.

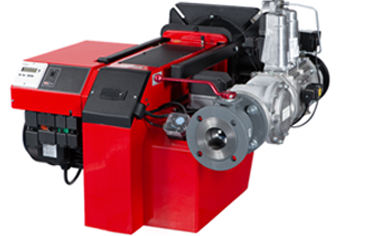

Pressure controllers are used to switch of the burner once set pressure is reached.

Boilers are fully insulated with 100 kg density 100 mm thick rockwool insulation and clad with GI sheets painted blue.

Isaac Boilers Pvt. Ltd is a leading manufacturer of cost effective package boiler system. We manufacture boilers as per IBR Code, BS2790 Standards and as per ASME Section VIII Div I Standards. As a policy we maintain the highest standards of quality and reliability in its products.

| Isaac Boilers Private Ltd | |

| Kalpadi - P.O, Kanniyakumari- D.T, | |

| Tamil Nadu – 629204. | |

| +91 7373799771 | |

| +91 8870220584 | |

| manuel@isaacboilers.com |

| P.O.Box 120866 | |

| Dubai .U.A.E | |

| manuel@isaacboilers.com |